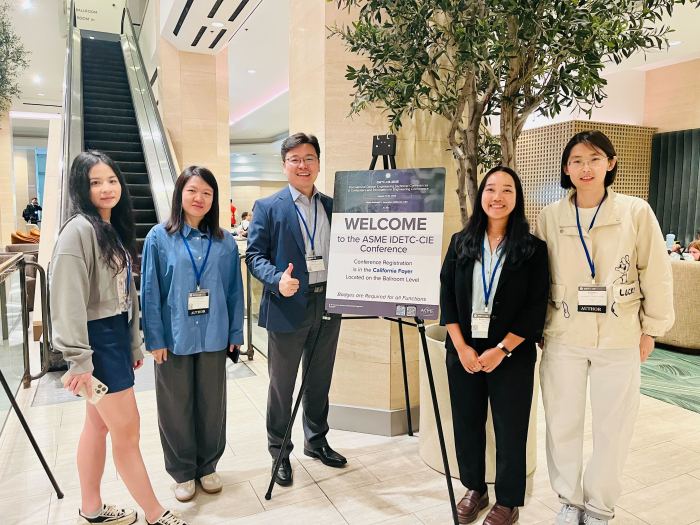

The conclusion of this year’s ASME IDETC/CIE conference marks the beginning of the academic year of 2025-2026. This year, SiDi Lab has five members attending the conference, including John Clay, Siyu Chen, Bam Thonkmak, Yuewan Sun, and Yinshuang Xiao. They were pretty productive and energetic in organizing workshops, participating in hackathon competitions, and presenting papers and posters. Meanwhile, it was such a proud moment to see the achievements and awards bestowed on SiDi lab members. Upon returning to the UT campus, let me reflect and summarize this conference trip.

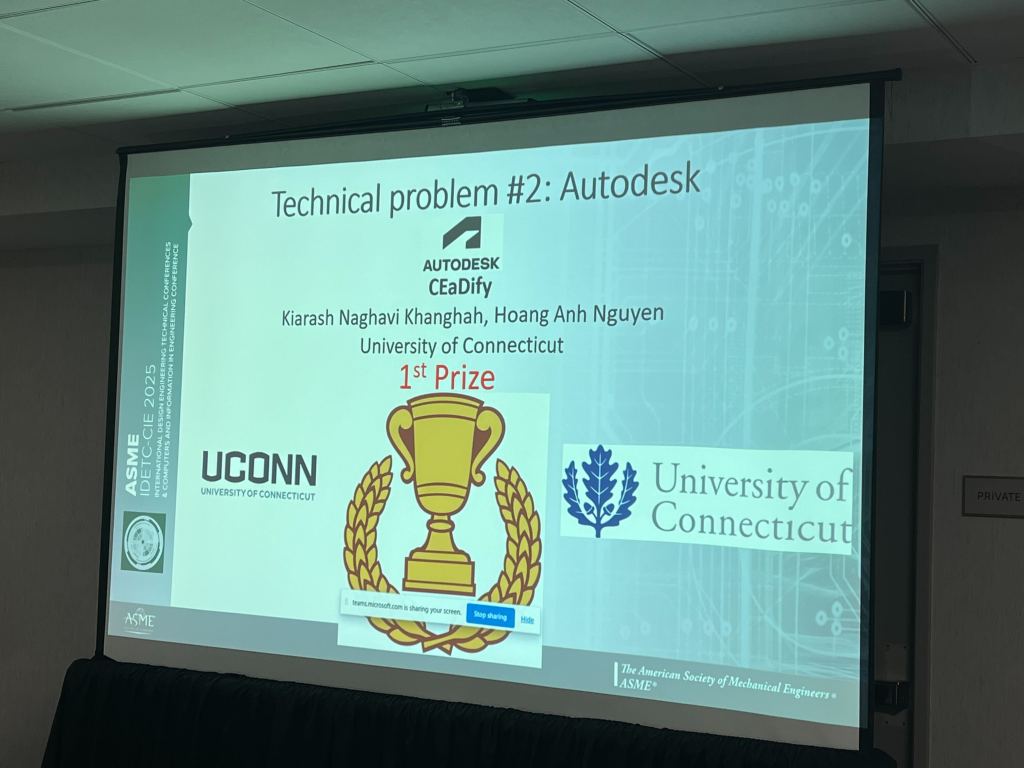

First, Year 2025 marks the sixth year of the ASME Hackathon – an important milestone as the event reached a historical number of participants. 58 participants from more than 33 institutions and 6 different counties gathered both in-person and online for a competition for three exciting problems sponsored by NIST, Autodesk, and nTop. I was delighted to see the growth and success of the student event that Dr. Yan Lu and I initiated six years ago, just before the COVID pandemic. Over the years, the hackathon event has received tremendous support from colleagues and friends in both academia and industry in helping achieve the goal we set at the beginning, i.e, we anticipate that the hackathon will generate society-wide impacts and become a signature event of ASME to promote the convergence between data science and mechanical engineering research and education.

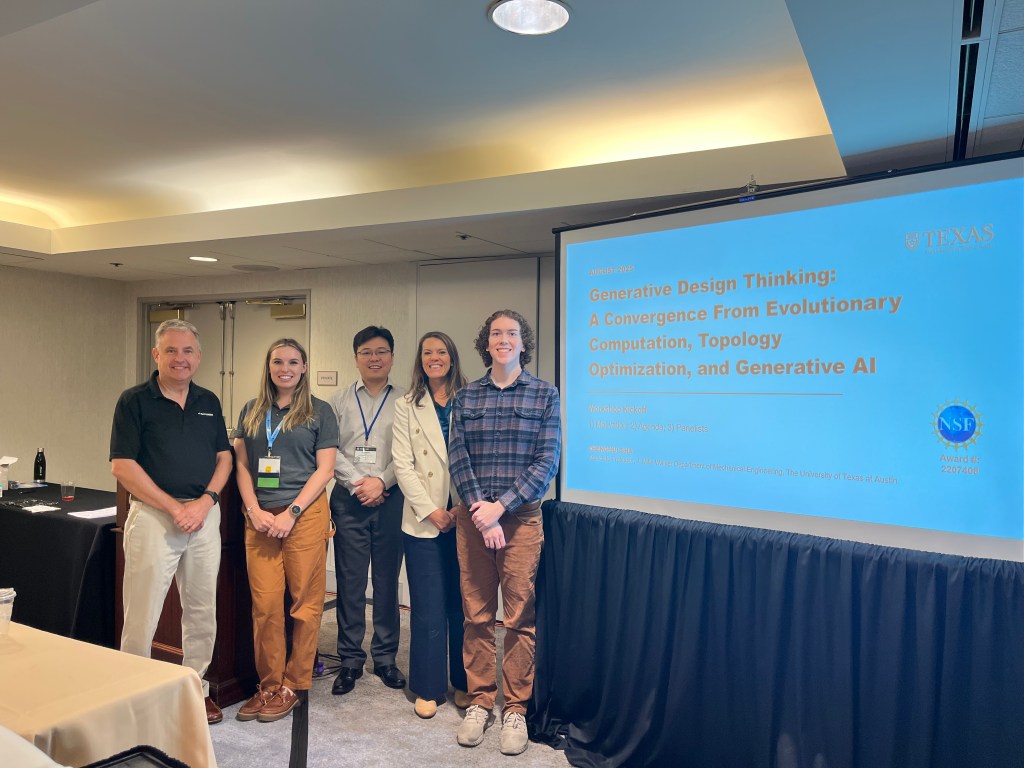

Second, it was exciting to organize the second Generative Design Thinking (GDT) workshop, reinforcing our research vision towards a new design thinking paradigm in the era of generative AI for the future of human-AI design collaboration and design education. We thank the support from all the panelists, including Dr. Molly Goldstein from UIUC, Dr. Charles Xie from IFI, Dr. Anastasia Schauer from UT Austin, and Daniel Banach from Autodesk. The SiDi research scientist assistant, John Clay, did a fantastic job putting all the efforts together and delivered another year of success after our first GDT workshop in 2024 in Boston, in partnership with Onshape.

Third, as the Special Program Chair of the Design Automation Conference (DAC) Executive Committee, I had the privilege of organizing the DAC signature event this year. The event featured a panel consisting of five speakers and domain experts in generative design, including Dr. Vinayak Krishnamurthy from Texas A&M, Dr. Leah Chong from UT Austin, Dr. Faez Ahmed from MIT, Dr. Ye Wang from EverCurrent, and Bradley Rothenberg from nTop. The topic of this year’s event is “Generative, Generative Design, and Generative Design Thinking.” The panel was a blast and my favorite of this year’s conference, and many of the conference attendees shared similar experiences with me. I wish I had more time to allow for more questions and interaction between the panelists and the audience. But it generates great momentum for further discussion on this topic.

Finally, kudos to all my students and co-authors. We presented a total of eight papers and one presentation-only submission:

- Y. Sun, Z. Sha, “TransformCAD: Multimodal Transformer for Computer-Aided Design Generation,” Proceedings of the ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025.

- Y. Xiao, H. D. Kaushik, J. Wang, J. Zhang, Z. Sha, “Electric Vehicle Charging Network Optimization Considering Regional Resource Dependencies,” Proceedings of the ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025.

- X. Li, Z. Sha, “Image2CADSeq: Computer-Aided Design Sequence and Knowledge Inference from Product Images,” Proceedings of the ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025.

- S. Chen, S. Bierschenk, D. Kovar, Z. Sha, “Constrained Bayesian Optimization for Robust Design of Complex Systems under Varying Operating Conditions,” Proceedings of the ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025.

- R. F. P. Stone, M. Ebert, E. Akleman, V. Krishnamurthy, Z. Sha, “MedialPart: Medial Axis-based Geometric Partitioning for Cooperative 3D Printing,” Proceedings of the ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025.

- C. D. Salazar, R. New, C. McCullough, T. Lassiter, K. R. Fleischmann, S. R. Greenberg, Z. Sha, R. G. Longoria, “Design, Development, and Testing of Smart Hand Tool Systems,” Proceedings of the ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025.

- N. Javadpour, K. Mutlu, Z. Sha, A. E. Bayrak, “Impact of Information Sharing Between Members in Design Teams Under Competition in Unknown Design Space Exploration,” Proceedings of the ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025.

- H. Sanam, A. Swaminathan, Z. Sha, “Computer Vision-based In-Situ Monitoring of Cooperative 3D Printing in A Closed-Loop System,” Proceedings of the ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025.

- P. Thongmak, H. Park, Y. Fu, Z. Sha, “A comparative study on vector-based and knowledge graph-based retrieval-augmented generation systems for product recommendation,” ASME 2025 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Anaheim, CA. August 17–20, 2025. Short paper and presentation-only.

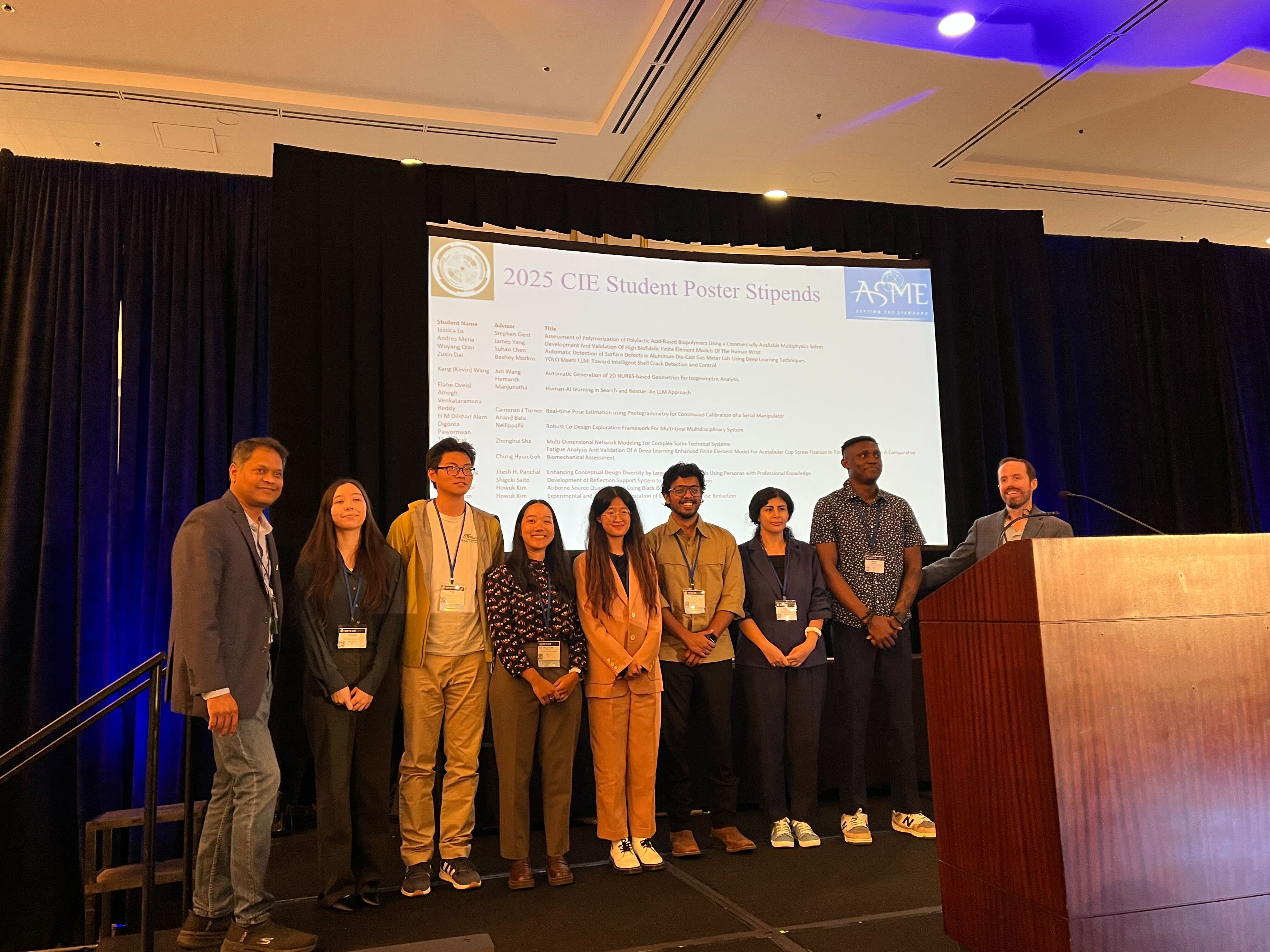

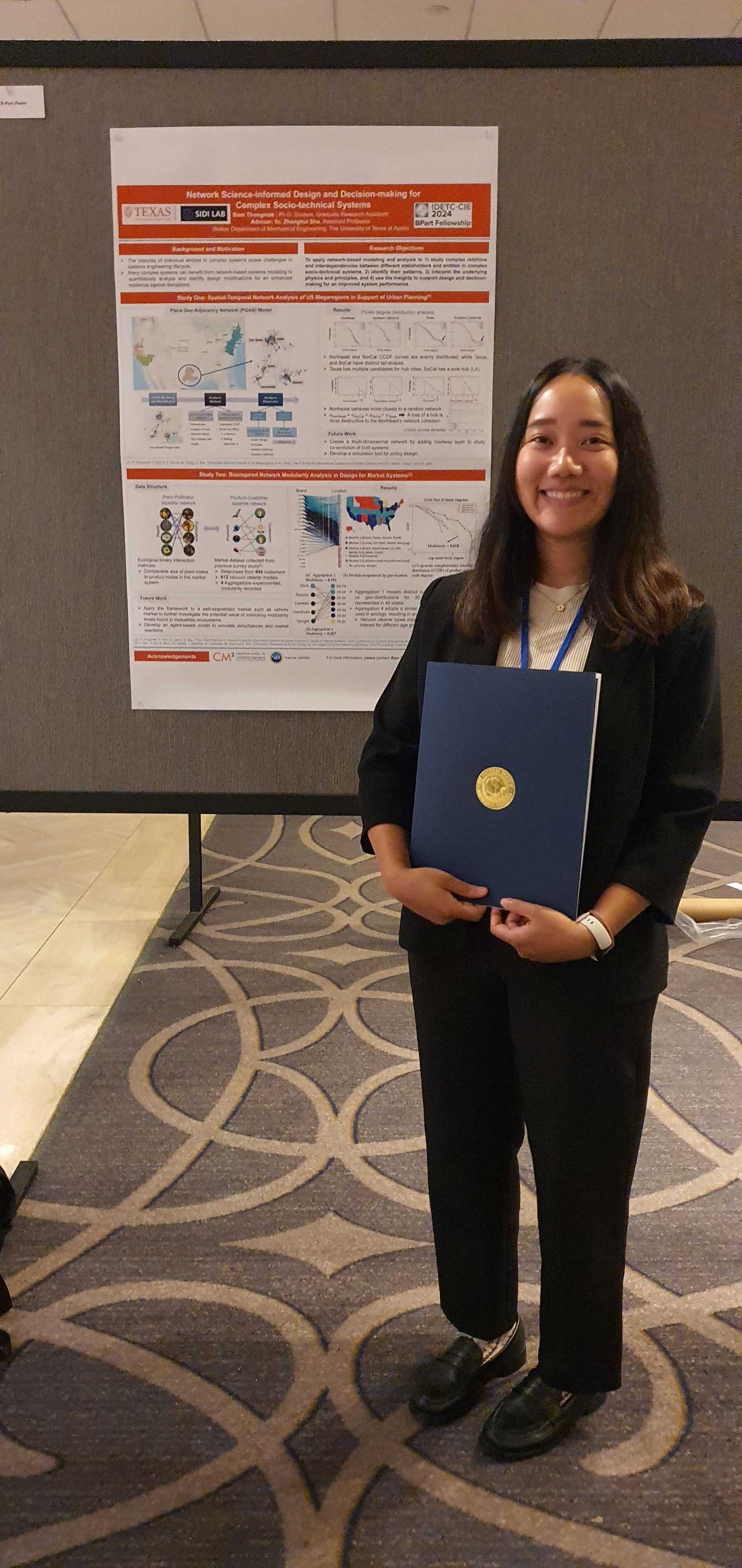

Among these papers and presentations, I would like to highlight the work led by my former PhD student, Xingang Li, on the topic of “Image2CADSeq: Computer-Aided Design Sequence and Knowledge Inference from Product Images.” This paper won the ASME Artificial Intelligence/Machine Learning 2025 Best Paper Award. Also, Bam Thongmak won a Travel Award for the ASME CIE Graduate Poster Competition, where she presented a poster introducing her dissertation research on “Multi-Dimensional Network Modeling for Complex Socio-technical Systems.” Congratulations to ALL!